CASING-REINFORCEMENTS

A tyre’s casing is made up of threads, the thickness of which varies according to the tyre range, makes it robust, flexible, efficient and lightweight. The more threads there are, the finer they are, making the tyre lighter. On the contrary, the less threads there are, the bigger they are, making the tyre stronger. TPI (Threads Per Inch) refers to the density of threads per inch.

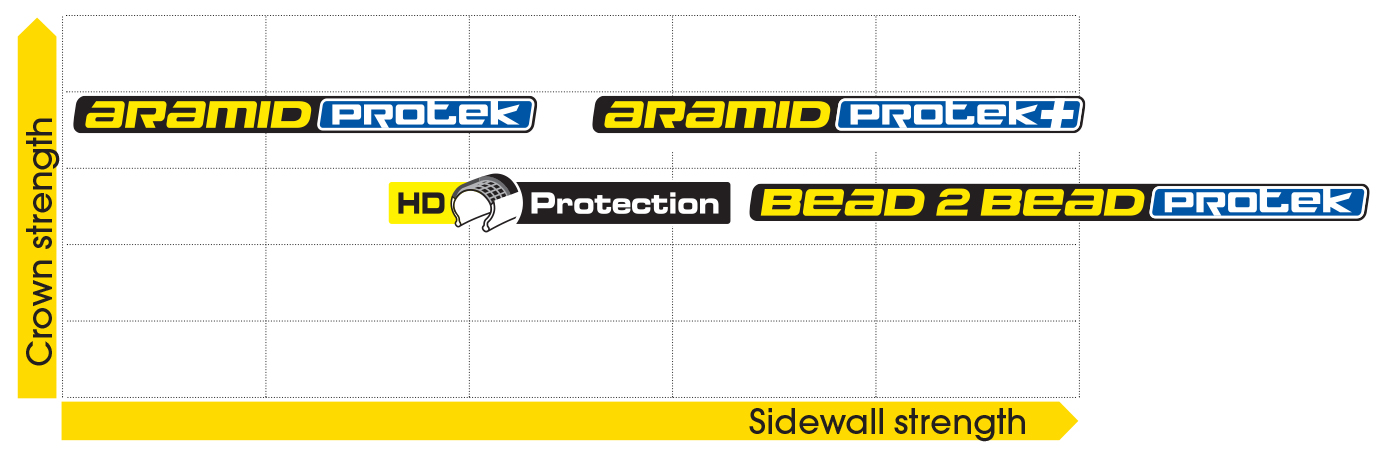

Reinforcement in the tyre casing to provide strength at the crown and minimise punctures. Aramid is stronger than traditional materials and is much more cut resistant. It is the material used for manufacturing body armor. (More than 200000km covered, puncture-free, by 200 experienced international riders)

RUBBERS

RUBBERS

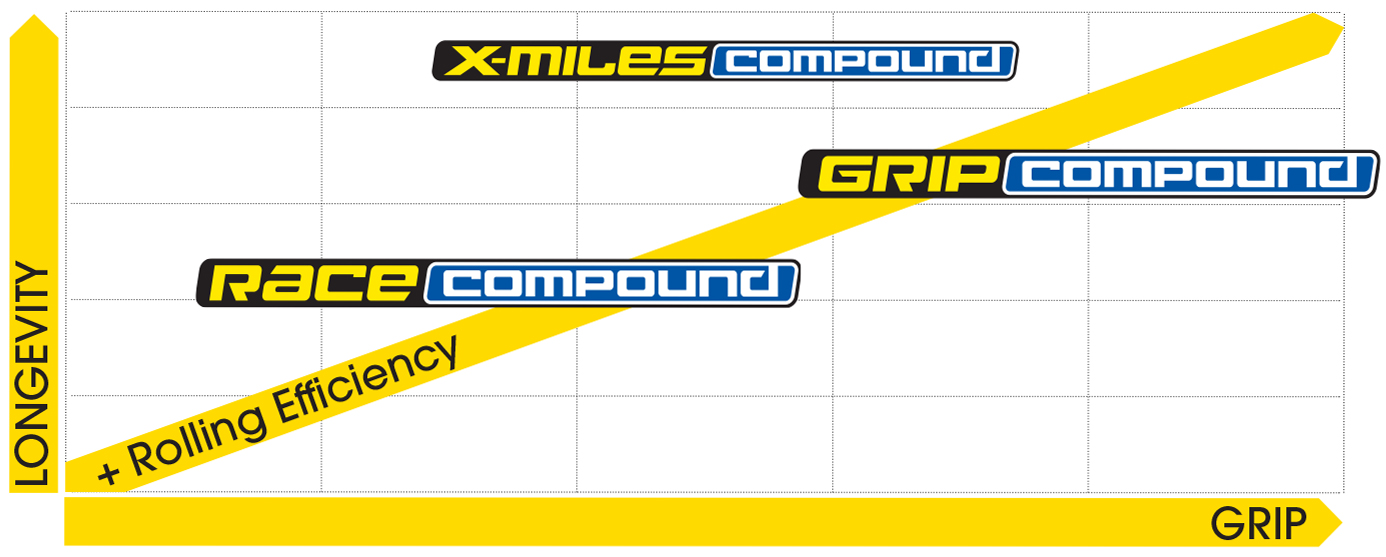

Rubber's characteristics give the tyre different performances. Rubbers can be either Mono-Compound or Bi-Compound.

A rubber compound with a low deformation rate, offering low rolling resistance. Derived from Moto GP technologies, this compound also provides excellent dry grip (Range: MICHELIN Power Competition).

Disc Brake Ready technology enables the tyre to withstand the powerful braking of bikes with disc brakes thanks to its special rubber.